SPACE

Winlight System supplies high-performance optical components, subsystems and test or calibration benches for space applications.

.

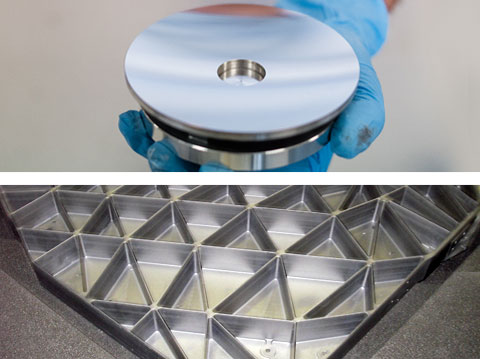

Winlight System supplies space-qualified components and subsystems to prime contractors in the space industry, not only in France but also worldwide, including the United States, to meet their requirements for weather, Earth observation and science satellites. These components and assemblies are thoroughly tested in thermal-vacuum chambers and on shakers to make sure they can stand up to the demanding space environment. Our optics are designed to meet these stringent requirements, whether made of aluminum, silica, CaF2, ZnSE, SiC or other materials.

We made the aspherical mirrors for the CHEMCAM instrument on the Curiosity rover, which recently completed its mission on Mars after far exceeding its planned lifetime. Building on this success, Winlight System also makes mirrors for Europe’s Mars 2020 mission, soon to be launched. We also make Optical Ground Support Equipment (OGSE), used to test the optical performance of satellite systems and make sure they can carry out their assigned mission.

Space optical components

& subsystems

At Winlight System, we make optical components and subsystems for space applications in full compliance with the sector’s demanding requirements: qualification and complete control of configurations, processes and checks. Our engineers are involved right from the initial design phase for the component or subsystem, all the way through construction and qualification, prior to building the flight model.

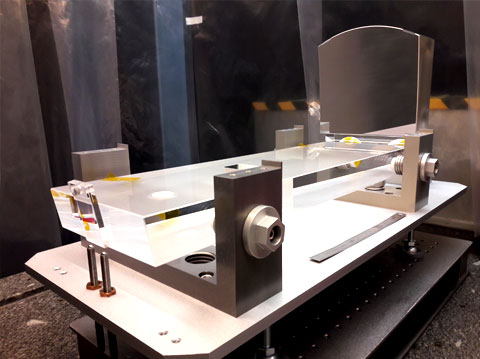

OGSE (Optical Ground

SUPPORT Equipment)

Optical Ground Support Equipment (OGSE) plays a vital role because it is designed to deliver the extremely high accuracy and reliability needed to validate flight instruments. This equipment is tested using state-of-the-art interferometry techniques to guarantee the flawless quality needed for spaceborne instruments.